Please count on us with all your super large/long products! We can treat super large/long products up to 1,300 mm in height, 1,300 mm in width and 1,650 mm in depth.

Japan's largest-class vacuum heat treatment plant

Vacuum heat treatment specialized manufacturer with super large vacuum heat treatment furnaces

Long experience in heat treatment

We have been operating vacuum heat treatment as our main business since 1973, quenching, annealing and applying specialized treatment on various types of parts for wide range of steels.

We can satisfy the needs of our customers with years of experience and our original heat treating techniques, not to mention product management.

Super large vacuum heat treatment furnace/3-chamber type vacuum heat treatment furnace

We own the largest-class vacuum heat treatment furnaces in Japan to handle products up to 1,300 mm in height, 1,300 mm in width, 1,650 mm in depth and 1,500 kg/gross in capacity.

These large vacuum heat treatment furnaces can handle mass-produced parts and lead to lower costs. We own 18 heat treatment furnaces to handle various types of heat treatments with shorter delivery time.

Examples of products treated in our super large vacuum heat treatment furnaces

| Material | Treatment method | Product size |

|---|---|---|

| SKD-61 | Quenching/tempering a long product | ⏀300×1,195L |

| SUS-304 | Solution treatment of a large product | 500t×500w×1,300L |

| SUS-420J2 | Quenching/tempering a large round product | ⏀1,130×400t |

Total vacuum process treatment (from cleaning to heat treatment)

From cleaning to heat treatment, all steps are processed in a vacuum environment of our company.

The advantages of treating in a vacuum environment include the superior capacity to remove dirt and oil on products by repeated vapor degreasing inside a furnace during the cleaning process.

We use non-polluting cleaning solutions to protect the environment.

In the heat treatment process, this prevents the formation of harmful coloring, oxide scale and decarburization.

Also, superior brilliance, stable hardness and small dimensional changes are its characteristics.

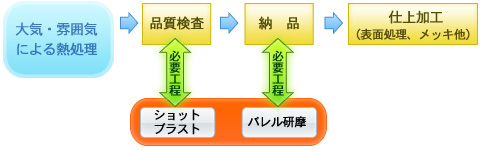

In case of atmosphere heat treatment

In case of atmosphere heat treatment, oxide scales are formed on the exterior of products. So it requires a removal process (shot blasting or barrel polishing), which would add extra costs to production and extra time to delivery.

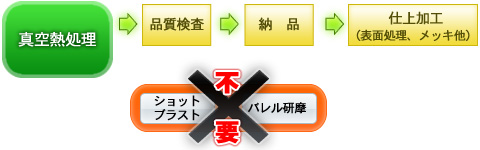

In case of vacuum heat treatment

In case of vacuum heat treatment, products are treated (heated up/cooled down) in a non-oxidizing environment (vacuum environment) to suppress the formation of oxide scales, rusts and such.Therefore, the appearance of the products is barely changed (although certain types of steels may have a coloring change depending on the treatment used), thus allowing us to skip the shot blasting and barrel polishing processes and cut costs and delivery time.